METAL BUILDING WINDOWS PLACEMENT FUNDAMENTALS, TIPS AND SAFETY

Windows can transform your metal building, bringing in natural light and airflow as well as adding design aesthetic.

Detailed specifications are key to ensuring that your supplier provides a proper metal building design that accurately places your windows and doors in the building. Keep in mind, the absence of a design professional (or architect) guiding the overall project will require you (the owner) to be responsible for providing the design criteria.

Metal Building Window Basics

The type of widow you put in your building is often related to the building’s use. You may consider installing upper windows to let natural light further into workspace, sliding windows to allow airflow or fixed windows which provide a tighter seal. The type of window you choose for your building may affect your rough opening size, so it is important to know this upfront.

There are differences between commercial rated and residential windows. Aluminum thermal broken frames are most common in commercial applications. “Wintech” is a popular commercial metal building window supplier that gives you the option to choose your window framing color. Residential windows such as vinyl, wood, or fiberglass frames can work as well, often at a lower price.

Overall window thermal performance is a function of the glazing, frame, and perimeter details. Typically, the overall goal in a climate-controlled workspace is to achieve the best possible daylight transmission while minimizing heat or cold transmission. Glass can be specified as insulated-double pane, non-insulated single pane, Low E-energy star rated, or to a specific code if known upfront.

For simplicity – to provide your building with a clean, streamlined look (and to ease the cost of construction) try to keep window sizes the same.

It is also recommended that you order your windows with plenty of lead time. This allows you to inspect the glass and verify that the windows are correct, preventing any construction scheduling delays.

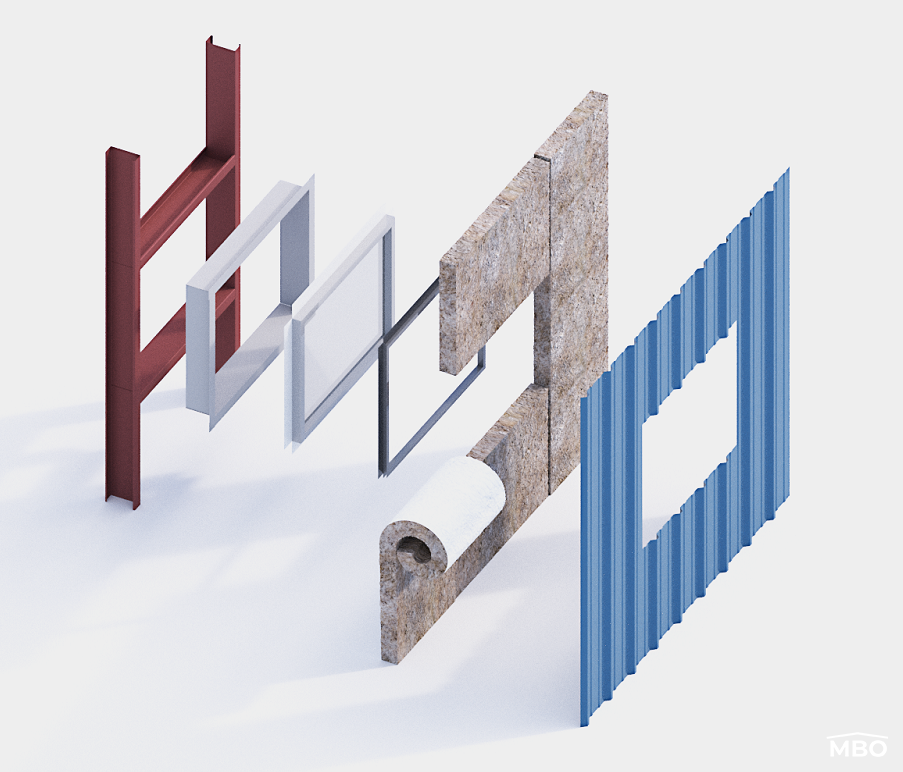

Components of a Framed Opening

The components of a window opening from Metal Building Outlet consists of structural framing made of 16-gauge C channel – with a finished J trim to help seal the assembly and provide a finished look. The depth of this framing commonly matches the building girt depth of 8 to 12 inches for a flush interior framing condition. An optional jamb, header and sill trim covering may be added for an interior finished look.

The top C channel, referred to as the “window header” and your bottom C channel, referred to as the “windowsill” are supported by (2) Channels referred to as “window jambs”.

When ordering windows. verify the outside window size, so the opening referred to as the “rough opening” is properly sized ¼ inch larger around – on all sides. A 4-foot wide by 3-foot-high opening takes a window size of 3’ 11 ½” x 2’11 ½” – which is a standard.

Window and door framing locations are commonly the most prone to air leaks and energy loss. Air leak testing is a current code requirement that is slowly being implemented by building departments nationwide. Make sure you spend extra time insuring gaps around window and doors are foam filled and sealed. It also helps to tape all loose insulation tabs and ends terminating into the steel framing.

Window Placement

A window frame can be ordered “Factory or Field Located” if the buyer has not determined the exact location. This is common. An experienced building erector often places the window to follow the high ribs of the exterior metal panel for a clean look and seal. Too many times we see window framing specified as “Field located” but important design criteria such as location and sill height (distance off finished floor) is missing.

The sill height (or bottom of the window height off the finished floor) is probably the most important measurement needed and can vary. Different variables such as an office sitting position or to a shop where the user is primarily standing can affect this. It is common to see sill heights 24 to 30 inches off the finished floor for offices and 48 inches for shops. A “field located” framing kit can be sized correctly by the metal building design team.

Here, an actual field located window frame kit with no vertical adjustment opportunities and required modifications in the field is shown.

It is important to provide proposed window locations to avoid relocation of bracing in the field.

Bracing

A metal building needs bracing. It is implemented into the overall design preventing frames from racking or toppling over during construction and carries through as a critical component in the overall design and certification. Bracing is necessary to control horizontal deflection of the superstructure frame to prevent door, window and interior finish cracking or deformations.

If you are planning to place a window in a section of the building where there is X bracing, you either must remove it and install a portal frame or leave the bracing in place over the window. These changes need to be done in the metal building design stage prior to fabrication. If you can live with a cable from the X brace, crossing in front of the windowpane, the cost of this special portal frame can be avoided. It is important to consider the bracing placement as well as the types of bracing.

Safety

It is important that you do not place windows (especially windows that slide open) high up in the building without fall out protection – for children. Installing the upper windows can be dangerous, so make sure you have the proper lifting equipment for the installation. Windows within 18” from the finished floor should be tempered glass. This is an essential code to follow when it comes to design. Windows should also meet the local code and wind load design requirements for safety.

Metal Building Outlet can help you with ordering your windows with your specifications. Contact a representative today for help configuring your project with window options.