Steel Crane Buildings

Metal Building Outlet provides innovative and cost-effective solutions for steel crane buildings. Our structures combine durability, versatility, and clear-span capabilities, creating optimal spaces for material handling, manufacturing and industrial operations. Whether you need a bridge crane building or a comprehensive solution for multiple crane systems, our structures deliver unmatched functionality.

Crane Options for Metal Buildings

An easy and economical method of moving bulky, awkward, or heavy items from one site to another, cranes are a fundamental component of many modern industrial metal buildings and manufacturing plants. These economic solutions utilize mechanisms like trolleys, hoists, fasteners and bumpers to relocate heavy cargo from one location within a building to another.

Metal Building Outlet steel buildings can be structurally designed to support three types of cranes: top-running, underhung and monorail cranes, to help with manufacturing and business endeavors. We can assist with all the structural design, providing brackets and sometimes the runway beam.

Underhung Bridge Cranes

Underhung cranes are trolley hoists that travel along a crane bridge by hanging from flanges. They are ideal when loaded hoists and trolleys must be transferred from one beam to another. Typically used to lift between 1 and 10 tons and travel between 20 and 50 feet, underhung cranes are available in either hand-powered or electric formats, the latter of which is generally operated via a pendant on the floor.

Great for large, open spaces and partial aisles, these cranes don’t need to extend completely between building columns because they utilize support brackets attached to building rafters. Generally more cost-efficient than top-running cranes, underhung models can be affordably coordinated with monorail trains if desired.

Top-Running Bridge Cranes

Top-running bridge cranes handle various loads and are ideal in steel buildings with minimal headroom. Single-girder cranes can lift between 1 and 20 tons, and those with wide flange girders can travel 20 × 60 feet. Those with double girders can lift as much as 100 tons and transport goods between 60 and 100 feet at a time.

Runway bumpers utilize springs or hydraulics and can be used to absorb the crane’s kinetic energy. Runway stops, as the name suggests, are used to stop a crane in motion, and top-running cranes must have a heavy bracket bolted at the top of the runway’s girders.

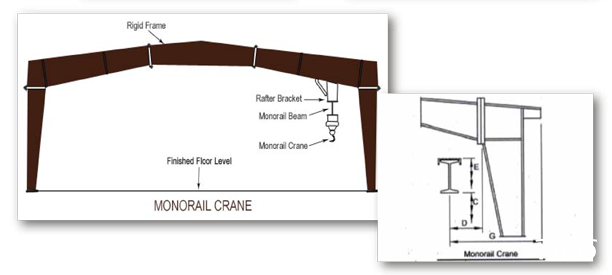

Monorail Cranes

A monorail crane utilizes a trolley that rides along the bottom flange of a runway beam to carry both the crane and hoist. Monorail cranes are designed to lift between 1 and 10 tons, and are available in electric and hand-geared formats. Commonly used in storage facilities, industrial manufacturing plants and maintenance facilities, monorail cranes offer an affordable method of transferring goods on a prearranged route that can be easily modified using switches or turntables.

Factors We Consider in Crane Building Design

Creating effective crane buildings requires meticulous planning and consideration of various critical factors. At Metal Building Outlet, we evaluate each project’s unique requirements to deliver structures that support your operational needs seamlessly. Key considerations include:

- Load capacity: We assess the maximum weight the crane system will handle to ensure that the building’s framework can support the heavy loads without compromising structural integrity.

- Span and clearances: We consider the distance the crane must travel horizontally and the ceiling height needed for lifting and maneuvering large loads.

- Wind and snow loads: Designing buildings to withstand local weather conditions, including high winds and heavy snowfall, guarantees durability and safety in diverse environments.

- Integration with building systems: The crane install should be a seamless integration of your crane building with electrical, plumbing and HVAC systems to optimize functionality and minimize operational disruptions.

- Crane runway support: The crane company should integrate runway beams into the primary framing and minimize or eliminate independent crane columns to save space.

Benefits of Steel Crane Buildings

Steel crane buildings offer unparalleled advantages for industrial and commercial applications:

- Durability and strength: Metal crane buildings are constructed with premium steel, providing exceptional strength and resilience against heavy loads and harsh weather conditions.

- Customization: You can tailor your crane building to meet specific operational needs, including varying crane types, sizes and additional features like mezzanines or specialized storage areas.

- Cost-effectiveness: Preengineered steel buildings offer a more affordable alternative to traditional construction methods, with lower maintenance costs and an extended life span contributing to long-term savings.

- Speed of construction: Prefabricated steel components streamline the building process, allowing for quicker assembly and reducing downtime associated with construction delays.

- Energy efficiency: Incorporating insulation and ventilation systems enhances energy efficiency, maintaining optimal indoor conditions and reducing utility expenses.

- Maintenance: Steel structures require minimal upkeep compared to other materials, saving time and resources.

Metal Crane Building Applications

Crane buildings facilitate overhead transportation of items in industries such as:

- Manufacturing plants

- Warehouses

- Automotive facilities

- Power plants

- Fabrication shops

- Construction sites

- Aerospace facilities

- Distribution centers

Why Choose Us for Your Steel Crane Building Needs?

Metal Building Outlet delivers top-tier steel crane buildings that meet your unique requirements. Here are some advantages of partnering with us:

- Competitive pricing: We leverage strong vendor relationships to provide cost-effective solutions.

- Comprehensive support: Our dedicated team provides end-to-end support, from initial consultation and design to installation guidance and after-sales service.

- Nationwide delivery: We offer delivery to projects across the U.S. and beyond.

- Unmatched expertise: With decades of experience designing and fabricating crane buildings, our team strives to deliver solutions that meet your specific operational requirements.

- Flexible designs: We provide customized building layouts for heavy lifts, multiple cranes or integrated mezzanines.

Request a Quote Today

Take your industrial operations to the next level with a durable, customizable steel crane building from Metal Building Outlet. Our expert team is ready to design and deliver a metal crane building that meets your specific needs and enhances your workflow efficiency.

Contact Metal Building Outlet for more about our available crane buildings and how we can help determine the best crane design for your needs and your building’s structural system.